Pavers Installation

Eminent Pavers

Installation Process

To produce consistent results, Eminent Pavers adheres to strict ICPI guidelines throughout the entire paver installation process. Each and every Eminent Pavers installation endures a rigorous inspection by a dedicated ICPI certified Project Manager to guarantee the highest standards of excellence are consistently met.

How We Install Pavers

1

Pavers Design & Planning: Eminent Pavers uses state-of-the art technology to provide fast, free and accurate on-site design consultations and price estimates. Our expert Project Managers guide you through the process every step of the way, as they work to transform your drab backyard into an amazing outdoor living space.

2

Pre-site Inspection: To make sure there are no surprises, your dedicated supervisor, and a dedicated project manager will meet with you prior to installation date to confirm every detail of your project and to answer any changes, requests, questions or concerns you might have.

3

Demolition & Excavation: When needed, professional heavy-duty machinery, such as a Bob-cat, will be used to demolish existing hard-scape surfaces, such as concrete or asphalt. Eminent Pavers uses industry standard practices and tools when demolishing customer property, regardless of the scope or scale.

4

Grading: Grading is included in most paving stone projects to create a natural slope for water run-off. All grading is performed with the final design in mind and provides an organic solution to element management.

5

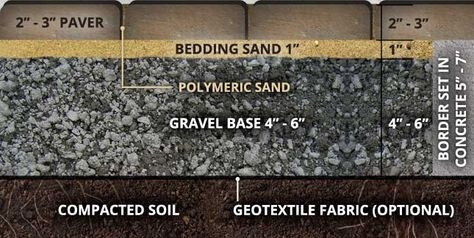

Sub Base & Base Compaction: While often overlooked by other contractors, Eminent Pavers utilizes professional quality compactors to compact the sub-base. This process ensures that there are no air gaps in the soil that may lead to unstable foundations or shifting pavers after installation.

6

Sand Installation: Eminent Pavers adds one inch of premium paver sand—debris free and designed for optimal bedding—on top of the compacted road base to assist with securing the paving stones.

7

Laying Pavers & Borders: Pavers are laid in the chosen pattern and according to ICPI guidelines for maximum length, lines and sizes to ensure a beautiful finish that will last for many years.

8

Polymeric Sand Installation: Eminent Pavers uses Polymeric sand—specially formulated sand for the filling your pavers joints. Unlike conventional sand which can be easily loosened and washed away by daily exposure to the elements, Polymeric sand binds the grains together to create solid, yet flexible joints that will maintain their bonds season after season, even in harsh climates.

9

Pavers Compaction & Polymeric Sand Activation: Eminent Pavers use a plate compactor to force the pavers securely into the bedding sand, ensuring maximum sturdiness and permanent positioning. During this process, bedding sand fills the paver joints, causing them to expand and “push” each paver, This assist with the interlocking action that will hold each paver in place relative to one another.

The polymeric sand used between paving stones is activated by spraying a mist of water over the joints. The water triggers the polymers and engages the binding process to hold the paving stones in place.

The polymeric sand used between paving stones is activated by spraying a mist of water over the joints. The water triggers the polymers and engages the binding process to hold the paving stones in place.

10

(Optional)Sealer Application: We recommend finishing the paver installation with a sealer to preserve the longevity of the stones, and to add a variety of professional looking finishes such as color enhancement or a wet look.

Client Feedback

This is the 2nd time we have used Eminent! The crew is punctual and is really fast. Only issue we had this time was turnaround time from another vendor and even when they came around, Eminent made us a priority and finished the job within a day's notice. Thanks Mark!

We are so very happy with our back yard pavers. Mark was so easy to work with and made sure we were happy with the progress every day of our 1 week project. We originally wanted stamped concrete but after Mark showed us the samples of pavers and the combination of the 2 colors, we were hooked. Our back yard went from ugly to demo to beautiful and useable. No more mud and stubbed toes. We had a few snags that were addressed and fixed right away. Overall I would recommend Eminent Construction to my friends and family and plan to get in touch with them again for our next project.

I requested Mark to build a flagstone patio and he did not disappoint. The quote and paperwork was done faster than I expected. He helped me communicating with the city, to comply with all the regulations to build the patio in my backyard. Very awesome service. On top of that, everything was completed really fast because Mark is a good supervisor and made sure his crew finished their tasks on time. I highly recommend this remodeling company.